M41

Power Meets Prestige

Crafted To Push Limits.

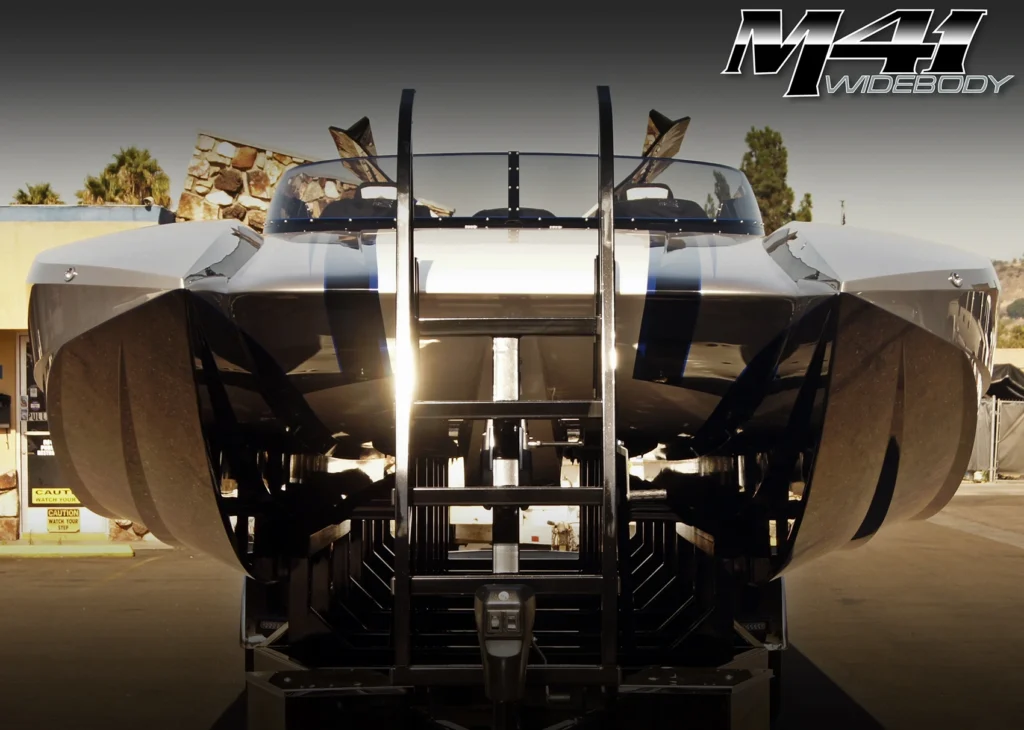

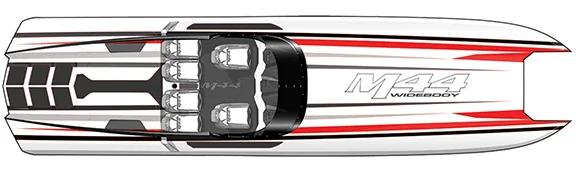

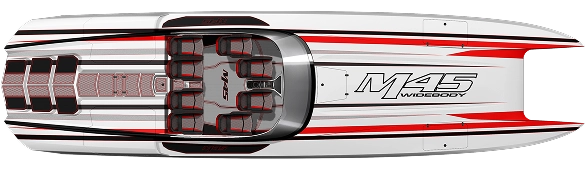

Bold in stature and flawless in execution, the DCB M41 Widebody is the third-largest offering in the elite M-Series lineup—and a true work of performance art. Designed by DCB founder Dave Hemmingson in collaboration with renowned automotive designer Rod Trenne, the M41 is a masterclass in precision and innovation, blending exotic styling with unmatched engineering.

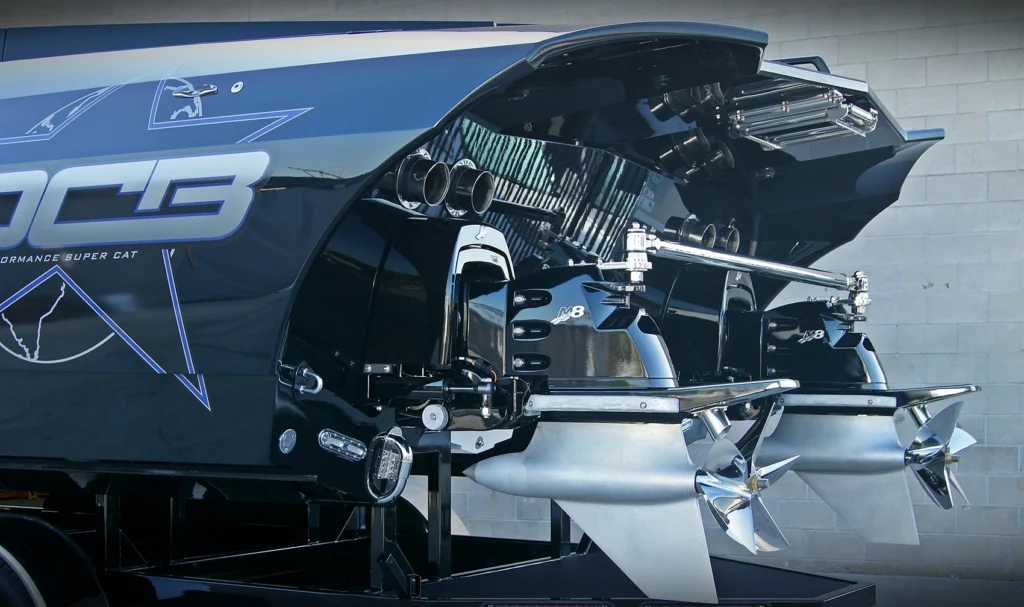

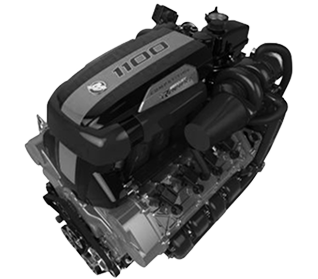

Raw Power

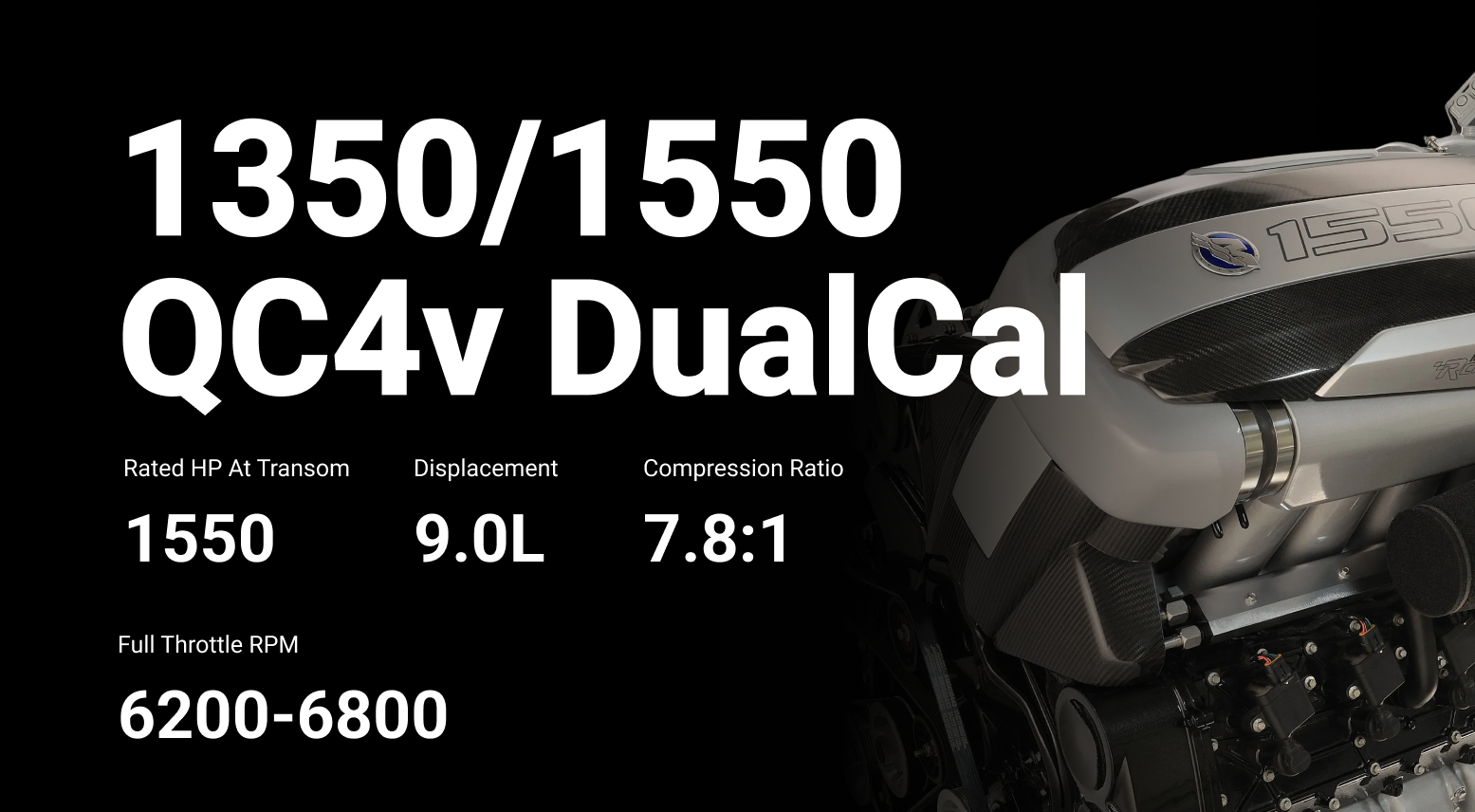

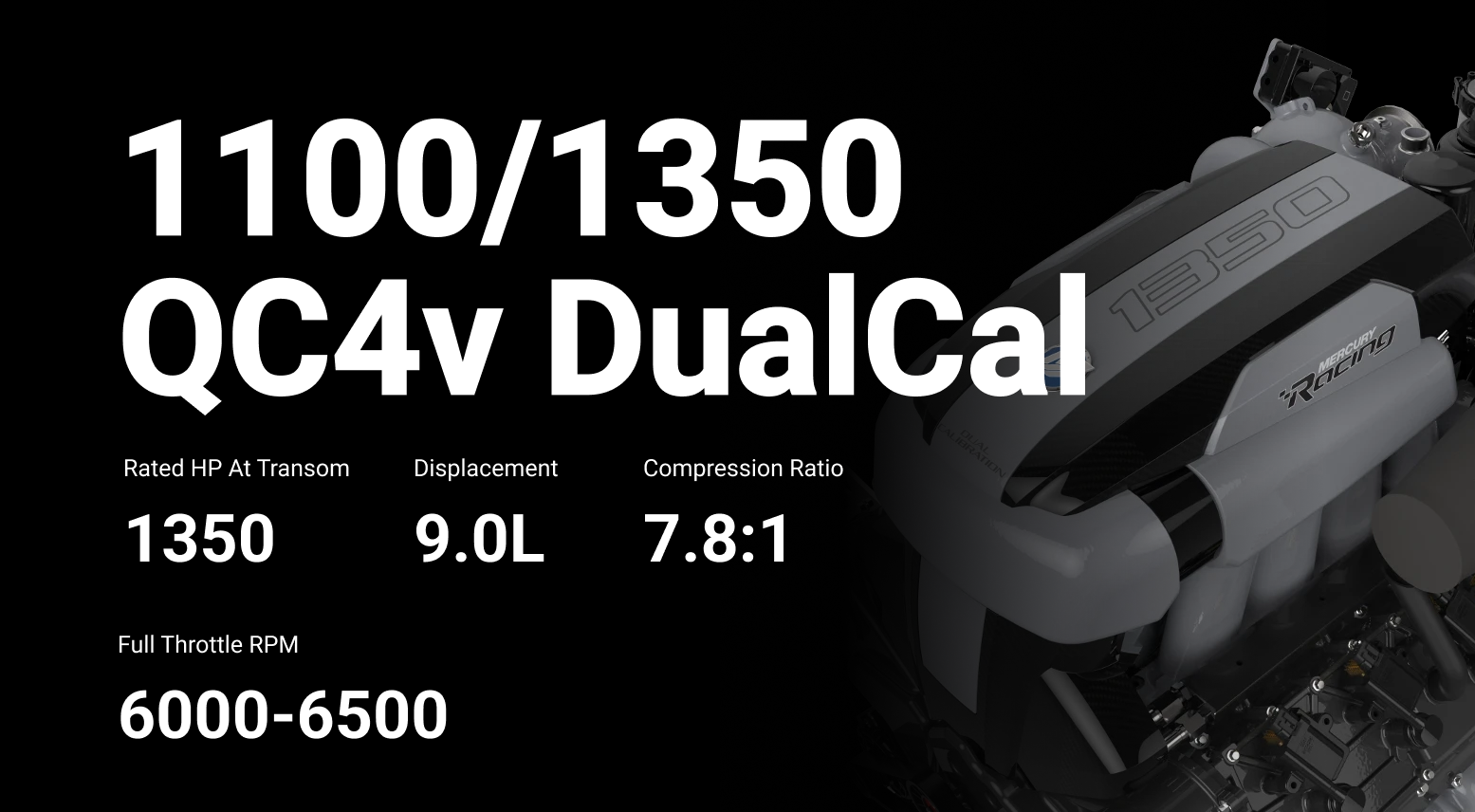

The M41 Widebody is powered by twin Mercury Racing QC4v twin-turbo stern drives, with available engine packages including the 1100, dual calibration 1100/1350, or dual calibration 1350/1550 — each offering raw power, proven reliability, and unrelenting performance. Paired with DCB’s most advanced centerpod hull design, the M41 delivers a composed ride, blistering acceleration, and precise handling at any speed.

Expertly

At 41 feet in length with a dominant widebody stance, the M41 redefines what’s possible in a high-performance stern drive catamaran. It is the first model in the industry to introduce Class A Surfacing, a technique borrowed from the world of high-end automotive design, where optical perfection and distortion-free reflections across the hull create a seamless, sculpture-like appearance. Every curve and contour was parametrically sculpted using Unigraphics NX CAD software, then brought to life through a massive 100-foot, 5-axis CNC milling process—resulting in a hull and deck that are as precise as they are beautiful.

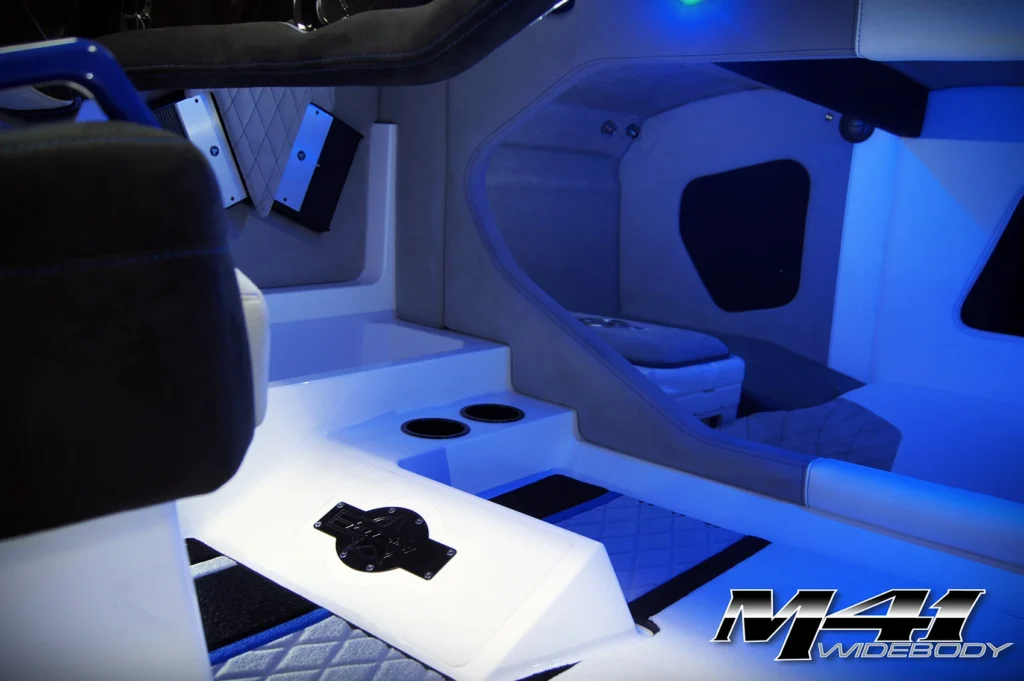

Handcrafted Interior

M41 six-seater blends luxury and performance with power-adjustable bolsters, billet footrests, an Alcantara dash with French stitching, and custom plush snap-in carpet. Every detail is designed for comfort and style.

Infotainment

A 7″ Garmin 743 delivers advanced navigation and engine data. Integrated with Mercury SmartCraft Connect, everything works seamlessly for a refined, intuitive boating experience.

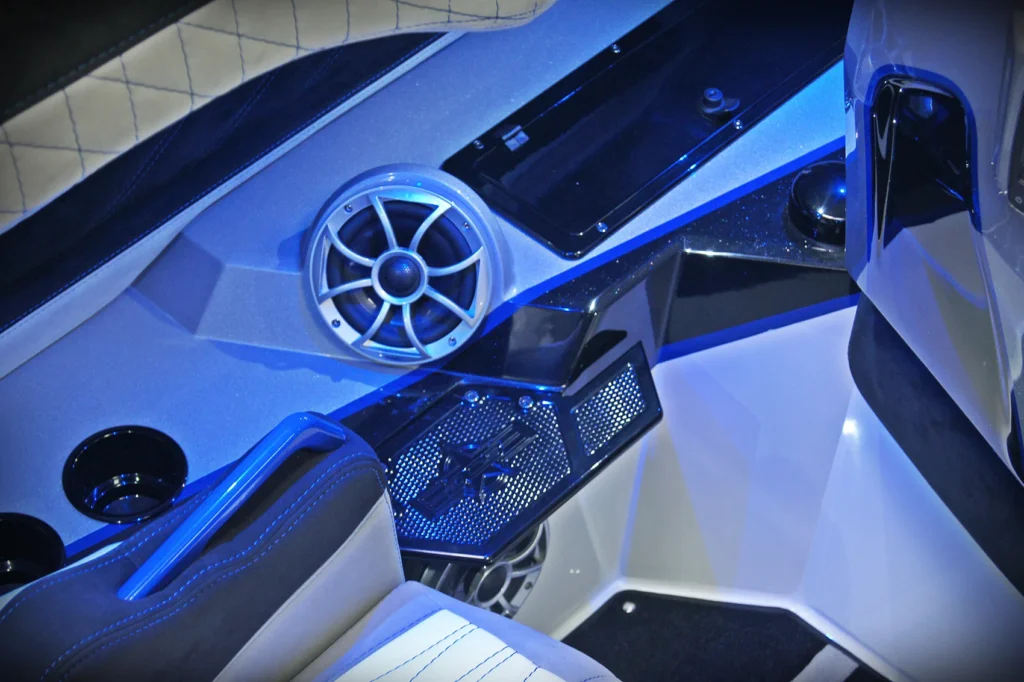

Stereo System

Our Phase 1 stereo system features a Fusion Marine Bluetooth/Wi-Fi head unit and four JL Audio 7.7″ speakers and two JL Audio 6.5” delivering rich, clear sound to match the boat’s handcrafted luxury and performance.

Custom Graphics

We collaborate with Wes Jones Design to deliver custom graphics. Every vessel features a premium gel coat finish with a striking black windshield register, complemented by high-gloss detailing.

Lighting It Up

Equipped with precision billet LED navigation lights, paired with a sleek nav/anchor light pole for optimal visibility. Full digital RGBW accent lighting under the dash, in cup holders, speakers, and an immersive atmosphere both day and night.

Built For Durability

Featuring exclusive DCB billet parts, three 1500 GPH bilge pumps, reinforced SS hardware, a 5/8‑inch thick acrylic windshield, and custom prop shaft covers—every detail is engineered for strength and reliability.

Premium Trailer

Our trailers feature a 10″ steel frame, torsion axles, disc brakes, 16″ aluminum wheels with spare, dual winches, tie-downs, a spare tire mount, and a courtesy ladder for easy loading. Numerous upgrades for both flat and tilt trailers allow you to fully customize to your needs.

Specifications & Construction

| Length | 40’10” |

| Beam Width | 10’10” |

| Hull Style | Center Pod Tunnel |

| Cockpit Seating | 6 |

| Cockpit Width | 89″ |

| Fuel Capacity | 2 x 125-gallon |

| Avg. Weight | 9,500-10,000 lbs |

DCB Signature Lamination Technologies

DCB catamaran hulls are manufactured using a proprietary lamination process designed for exceptional strength, durability, and performance. For select models such as the M28, M31, and M35, the construction process features DCB PerformaLam—a custom-engineered lamination schedule that blends advanced materials with elite craftsmanship.

DCB PerformaLam

PerformaLam features our exclusive Vacuum Infused Resin (VIR) technology combined with a high-performance blend of bi-axial E-glass, Kevlar, high-density balsa, and other proprietary materials. This process ensures consistent resin saturation and complete air removal, resulting in a strong, rigid, and precisely engineered hull.

Slightly heavier than AeroLam, PerformaLam delivers exceptional structural integrity, impact resistance, and overall value. It is a purpose-built solution designed for dependable, high-speed performance with confidence and control.

Every PerformaLam hull is a testament to DCB’s commitment to advanced engineering and meticulous craftsmanship, purposefully built for those who demand performance without compromise.

Precision

At DCB, every boat is a masterclass in engineering excellence. Our proprietary Vacuum Infused Resin (VIR) process ensures perfect material saturation for unmatched strength, rigidity, and weight savings—far beyond conventional vacuum bagging. Backed by composites engineers and crafted by the industry’s finest, each DCB hull combines advanced materials into a structure that redefines performance. This is construction at its highest level—where innovation meets obsession.

VIR Technology Advantage

Composite Expertise

Built with Obsession

Unrivaled Engineering

Built By Hand

Inside, the M41 seats six in a cockpit that embodies DCB’s obsessive attention to detail—featuring premium upholstery, custom finishes, and fully integrated controls. Every stitch, every angle, and every component is built to the highest standard, making the M41 as refined as it is ferocious.