Every DCB is the result of a meticulous, multi-stage process driven by precision, passion, and performance. From concept to completion, each boat is handcrafted by our elite team of artisans and engineers—united by an unwavering commitment to excellence. The journey begins with visionary design, advances through state-of-the-art construction and expert rigging, and culminates in rigorous testing. Featured here is the step-by-step evolution resulting in a one-of-a-kind masterpiece of performance engineering.

Every legendary DCB boat begins with three foundational steps: Design. Plug. Mold. This is the birthplace of performance and precision. The beginning of a journey where innovation meets craftsmanship.

Naval architects use 3D modeling and performance data, combined with hydrodynamic and aerodynamic calculations, to design the functional running surfaces, practical features, and aggressive posture of the hull and deck molds.

A 5-axis CNC mill is used to create a full-sized, completely symmetrical plug from which the mold itself is made.

The finished plug is converted into the full-scale mold. A steel frame and tube structure adds strength, rigidity, and mobility.

At DCB, every boat is meticulously crafted through a comprehensive 10-step build process that covers every aspect of design, engineering, and construction. This proven process ensures uncompromising quality at each stage—while leaving room for infinite customization.

From hull design to finishing touches, each step is guided by your unique preferences, personality, and performance goals. Every DCB boat is custom-built from the ground up to reflect the vision of its owner. The result is more than a boat—it’s a one-of-a-kind masterpiece that doesn’t just turn heads, it fulfills a dream.

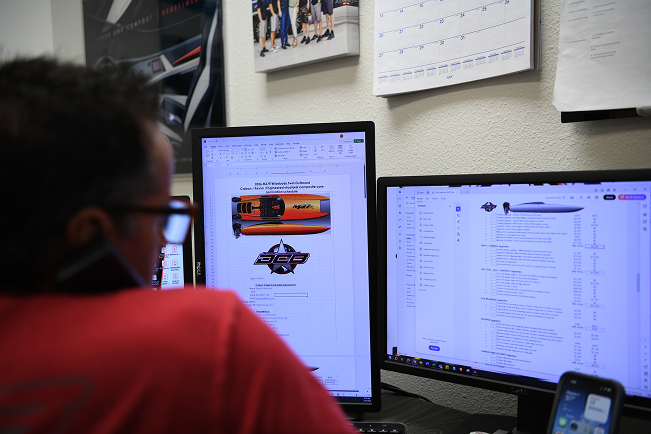

Selections

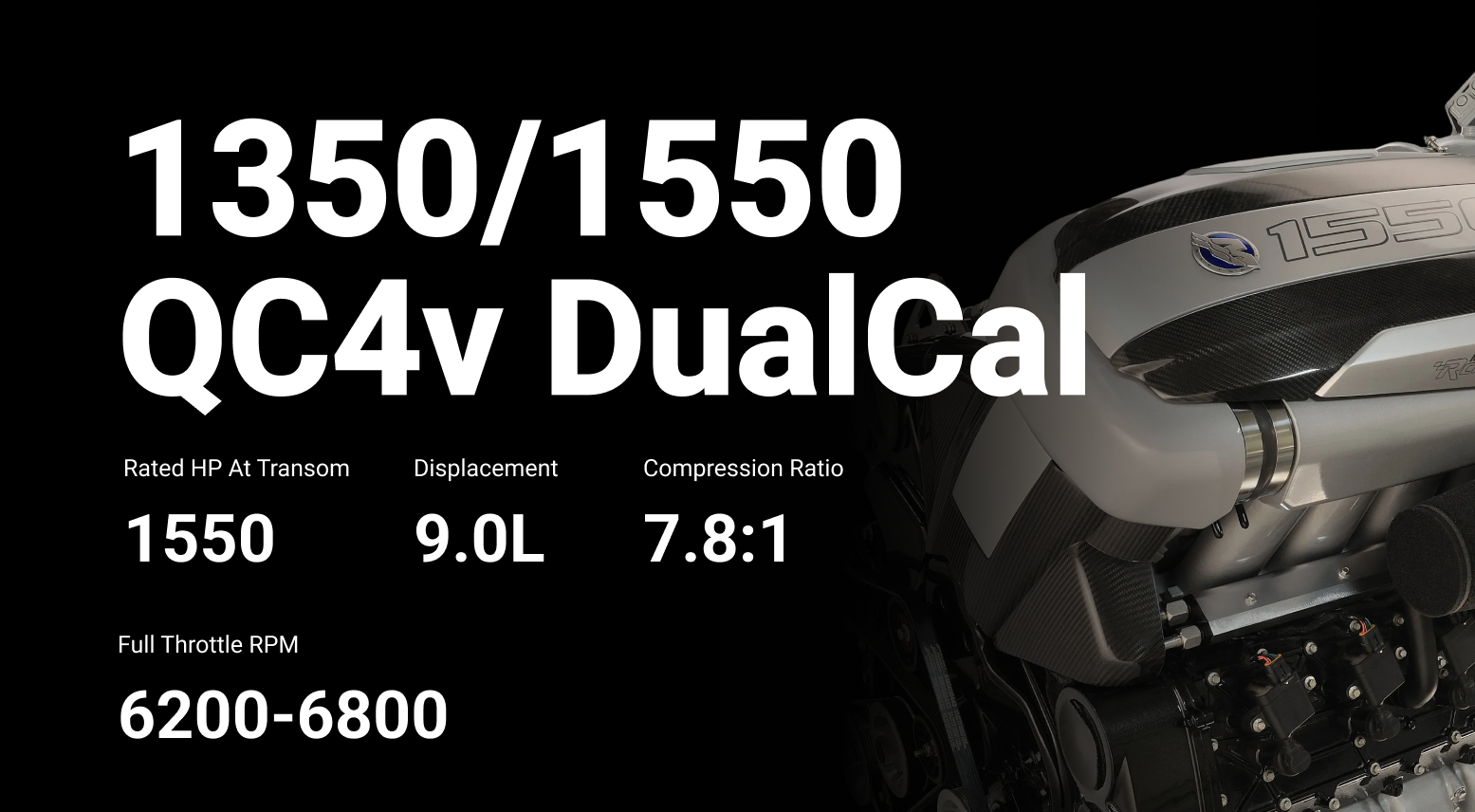

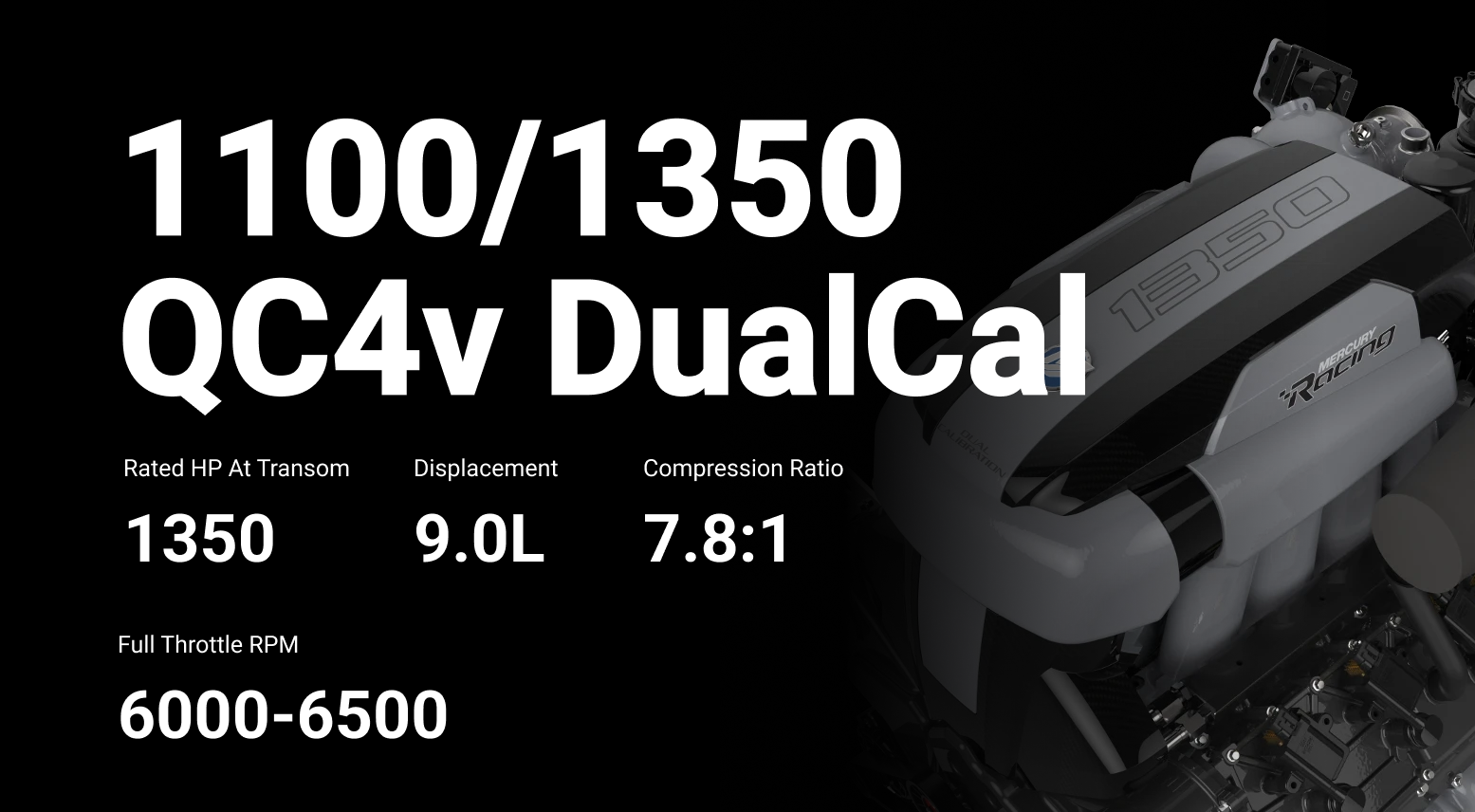

Our customized build sheets are highly detailed. One of our knowledgeable team members will work with your family throughout the process, helping you select the model, engine power, base color with graphics, interior, and all available options. Once complete, the build sheet will be emailed to you and will include full pricing.

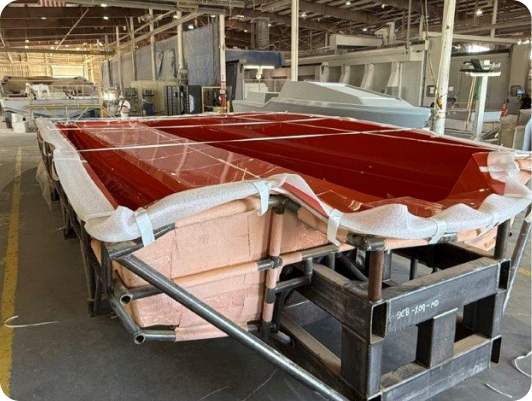

Mold Preparation, Masking, and Gelcoat Application

In this step, every mold is thoroughly cleaned and waxed with a special release agent, allowing the hull and other components to release cleanly from the mold after curing. The waxed mold is then meticulously taped off so that the base color, lettering, numbers, and graphics appear in the selected locations. After masking, a color‑pigmented resin called gelcoat is expertly sprayed in a specific sequence to achieve the customer’s desired final appearance.

Lamination, Construction, and Stringer Installation

Using a highly refined and proprietary process, DCB combines 7 to 9 layers of different materials, including carbon fiber, Kevlar, and high‑density coring, arranged in a precise sequence to create the hull and deck. Stringers, which provide critical longitudinal support, are structurally integrated during this stage of the manufacturing process. These exclusive, time‑tested methods ensure every DCB boat is exceptionally strong, impressively lightweight, and finished to a standard second to none.

Vacuum Infusion Resin (VIR)

The VIR process is a closed‑mold manufacturing technique used to produce our composite hulls, decks, and subcomponent parts with exceptional strength‑to‑weight ratios and superior surface finishes. It begins with placing the composite materials into the mold, sealing it with a hand‑installed vacuum bag, and then using vacuum pressure to draw resin evenly through the layered materials. This process ensures complete resin saturation, removes excess resin for optimal weight reduction, and delivers consistent thickness throughout.

Bulkhead Installation and Top Deck-to-Hull Pairing

During this process, two critical steps are completed. The structural vertical walls, known as bulkheads, are manufactured from composite materials and engineered shapes, then adhered in place at precise spacing intervals. These structures provide strength, distribute loads, and resist twisting of the hull and deck. Once the bulkheads are installed, the top deck is carefully lowered into place using overhead cranes. The top deck and bottom hull are then precisely fitted and bonded together along what is called the bond line. This line is typically covered by a rub rail, for a seamless premium appearance, or it can be made to disappear entirely by selecting the optional full cap feature.

Surface Finishing

After the bottom mold and top deck are bonded and paired together, the boat moves onto the next step, which is surface finishing. Literally hundreds of man-hours are spent dry sanding and wet sanding, starting with 1000-grit and ending with 2500-grit sandpaper. Every square inch of the boat is painstakingly hand-sanded to an industry-leading level, smoothing out all exterior surfaces of the entire boat. Afterwards, this department moves on to buffing. During which a combination of buffing pads and polishing compounds are utilized to bring forth a flat, even, and high shine final finish gelcoat surface. We consider this a particular strength of our brand.

Upholstery / Interior

A standout in the performance boating industry is our award-winning interiors. We offer our customers a complete package of comfort, ergonomics, functionality, and unique jaw-dropping interiors. Customers building a new boat or updating a used boat can select from a variety of materials, embroidery, thread and piping colors, stitching patterns, material color, and textures. 3-D pattern design and shaped perforation designs can be used in combination to arrive at your dream interior. All seats, side panels, and the dash are sewn in-house using both modern CNC machinery and traditional skilled craftsmanship, hand sewing. For the flooring, the customer may select a foam floor, carpeted floor, or carpeted floor on top of a foam floor.

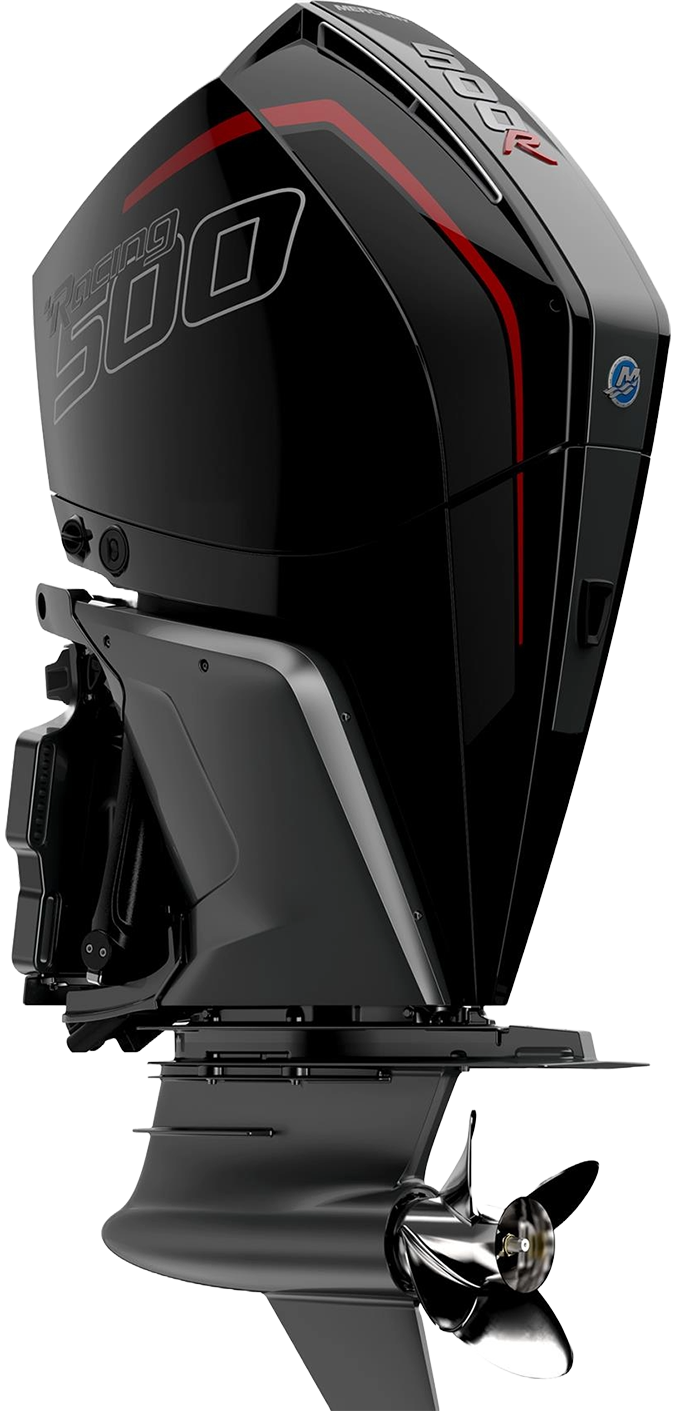

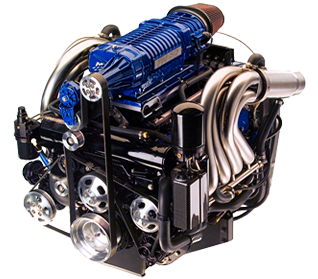

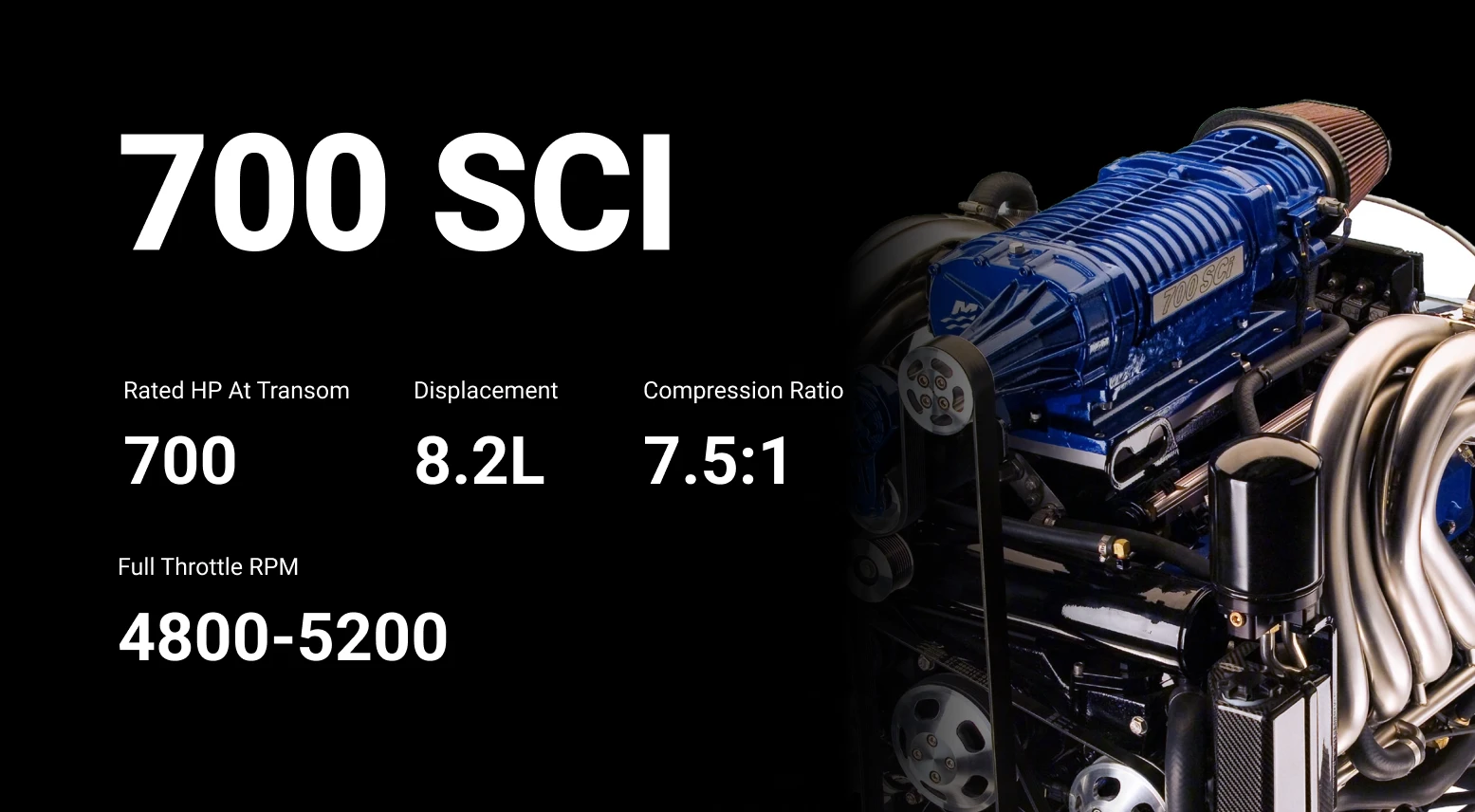

Final Rigging Department

This department is where it all comes together. Our skilled trade professionals install the boat’s engines, the dash and seats, the screens, the stereo, the lighting equipment, the windshield, and all the hatches. DCB exclusively uses only the finest quality brand-name components. Everything is neat and organized with a very high level of attention to detail. Anywhere you can look on a DCB boat, you will find a refined fit and finish.

Boat & Trailer Pairing

After a DCB boat is fully completed, it is paired with the selected trailer. As shown, the boat is suspended using cranes and the trailer is slid underneath. Our factory checks for proper boat-to-trailer fitment and uses high-quality Mac’s ratchet straps to secure the boat to the trailer. Whether the trailer is a tilt or a flat trailer, we offer 4 trailer brands for our customers to choose from. A wide variety of trailer features and options are available to meet our customers’ needs and budget.

Final Testing, Safety, and Systems Checks

Every DCB boat goes through a rigorous final quality control process. We have developed a written checklist that at least 2 of our most veteran team members must approve and sign off on. Each boat is on-water tested to ensure every aspect of the boat is functioning properly at all speed intervals. This list is available to customers upon request. We remind customers of the importance of taking a performance boating class. Qualified instructors are on the DCB website. After delivery, we hope the boat that we have created together, goes on to provide your family with years of great memories.